For decades, quality control depended on human eyesight, experience, and a fair amount of routine. That model worked when production lines moved slower and defect tolerance was higher. Today, scale and speed leave far less room for missed flaws, and computer vision for quality control has become a practical response to that pressure, not a futuristic add-on.

Instead of asking people to spot the same defect hundreds of times per shift, companies are teaching systems to see patterns humans eventually miss. Cameras, sensors, and trained models continuously inspect products, flag anomalies in real time, and do so without fatigue or bias. The shift is not about removing humans from the process, but about letting them focus on decisions and exceptions rather than on repetitive tasks.

This article breaks down:

- Why manual inspection struggles in modern production environments

- How computer vision systems actually work on the shop floor

- Where automation delivers the biggest quality and cost gains

- What to consider before starting an implementation

Keep reading to see how inspection is changing and what a realistic computer vision implementation looks like in practice.

What is computer vision and how it works in quality control

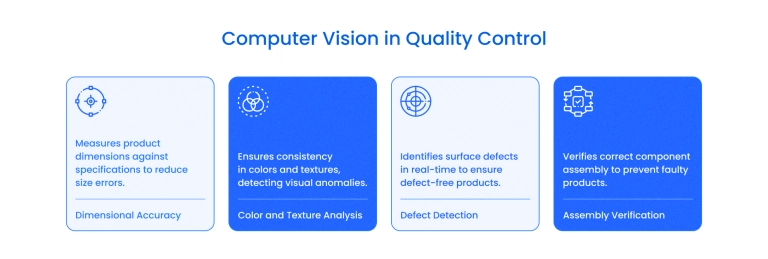

Computer vision gives machines the ability to inspect products the way humans do, but with far greater consistency and speed. In quality control, cameras capture images of parts or products as they move through production, and trained models analyze those visuals to spot defects, deviations, or anomalies that fall outside defined standards.

This is how quality control with computer vision shifts inspection from subjective judgment to repeatable, data-driven decisions.

At a basic level, the system learns what "acceptable" looks like by analyzing thousands of reference images. Once deployed, it compares every new item against that baseline, flagging issues such as surface defects, misalignment, or damage in real time. The result is earlier detection, fewer escapes, and a feedback loop that helps manufacturers correct problems before they scale.

The limitations of manual inspection

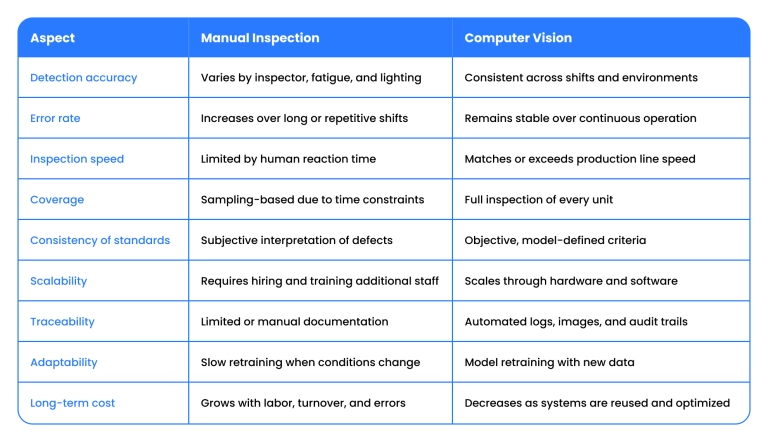

Manual inspection tends to break down under modern production conditions, not because inspectors are careless, but because human attention and perception are finite.

Repetitive visual tasks, time pressure, and environmental noise all contribute to variability that is difficult to eliminate with training alone. These structural constraints are a key reason why computer vision in quality control has gained traction across manufacturing and industrial operations.

The most common limitations of human-based inspection include:

- High defect miss rates: Studies show that inspectors can miss 20–30% of defects during repetitive visual checks. As inspection cycles repeat, the brain becomes less sensitive to minor anomalies, allowing defects to pass unnoticed until later stages.

- Inconsistent accuracy across shifts and inspectors: Manual inspection accuracy can vary widely, often ranging from 60% to 90% depending on lighting, workload, and individual experience. This variability makes it challenging to enforce uniform quality standards at scale.

- Fatigue and attention drift: Long shifts and monotonous inspection tasks reduce concentration over time, increasing the likelihood of missed defects toward the end of a work period. Even experienced inspectors are vulnerable to performance decline under sustained visual load.

- Sampling instead of full inspection: Because manual inspection is time-intensive, many operations rely on spot checks rather than inspecting every unit. This approach reduces immediate labor costs but creates blind spots where defects can slip through undetected.

- Subjective judgment and interpretation: Human inspectors often rely on personal judgment when evaluating borderline defects. As a result, the same imperfection may be classified differently by different inspectors or at different times, leading to inconsistent outcomes.

These limitations explain why manufacturers increasingly adopt automated inspection systems that apply consistent criteria to every unit. This shift toward computer vision for quality inspection helps eliminate variability while improving coverage and reliability across production lines.

Why computer vision wins: Key advantages

Automation wins in quality control because it removes variability from the equation.

Computer vision systems inspect every item using the same logic, thresholds, and reference data, regardless of shift length or production speed. This consistency defines the role of computer vision in quality control, especially in environments where even small defects can lead to recalls, downtime, or safety risks.

Unlike manual inspection, computer vision relies on trained models rather than individual judgment. These models are built on large volumes of visual data, tuned to specific defect patterns, and refined as conditions change.

That is why manufacturers often turn to experienced computer vision for quality control providers or invest in custom computer vision development to align inspection logic with real production constraints instead of relying on generic, one-size-fits-all tools.

The advantage is not incremental efficiency, but structural stability. Computer vision transforms inspection into a controllable, auditable process that scales with production rather than slowing it down.

Key components of a computer vision quality control system

A reliable inspection system is built from several interdependent layers. Weakness in any one of them, whether hardware, data, or integration, directly affects accuracy and trust in results. This is especially true in computer vision quality control manufacturing, where systems must perform under real production constraints, not lab conditions.

Cameras and sensors

Everything starts with how visual data is captured. Industrial-grade cameras, lenses, and sensors must match the production environment, including speed, lighting variability, vibration, and material properties.

Resolution, frame rate, and placement determine whether defects are visible at all, long before any AI model is involved.

Data and image quality

High-quality input data is non-negotiable. Consistent lighting, controlled backgrounds, and calibrated setups reduce noise and false positives. Poor image quality cannot be fixed downstream, which is why successful systems invest heavily in preprocessing, normalization, and continuous monitoring of data drift.

AI models and algorithms

At the core sit machine learning models trained to recognize acceptable patterns and deviations. These models may rely on classical vision techniques, deep learning, or hybrid approaches, depending on defect complexity.

The key is not model sophistication, but alignment with real defect types, tolerances, and edge cases observed in production.

Annotation and training pipelines

Behind every accurate model is a disciplined labeling process. Defect annotations must be precise, consistent, and updated as products or materials change. Mature systems treat annotation and retraining as ongoing processes, not one-time setup tasks.

Integration with production systems

Inspection results only matter if they trigger action. Computer vision systems must integrate with MES, ERP, PLCs, or quality management platforms to stop lines, flag batches, or generate reports. This integration ensures that insights flow directly into operational decisions rather than remaining isolated in dashboards.

Edge and infrastructure layer

Processing location matters. Some inspections require near-zero latency and run on edge devices, while others benefit from centralized processing. Hardware acceleration, redundancy, and failover planning are essential to keep the inspection running without disrupting production.

Monitoring, metrics, and feedback loops

Production conditions evolve. Lighting changes, materials vary, and defect patterns shift. Continuous monitoring, confidence scoring, and feedback loops help teams detect performance degradation early and retrain models before accuracy drops.

While these components are standard across industries, their balance differs by domain. Lessons from regulated environments, such as computer vision in healthcare , often translate well to manufacturing, where traceability, reliability, and system validation are just as critical.

Transform your operations with custom computer vision solutions tailored to your needs

Use cases of computer vision in quality control across industries

As organizations rely more on visual data to make decisions, quality control extends beyond physical defects into process validation and compliance. Computer vision systems help standardize how visual inputs are evaluated, making quality control with computer vision and sensing a practical layer across both industrial and digital workflows.

Healthcare

In healthcare, quality control focuses on precision and safety. Computer vision inspects medical devices, verifies sterile packaging, and checks labeling accuracy before products enter clinical use. In imaging workflows, it also validates image quality and detects anomalies that could compromise diagnostics, reducing the risk of human oversight in high-stakes environments.

Fintech

Fintech platforms process large volumes of visual documents, from identity verification to transaction evidence. Computer vision ensures images meet quality thresholds, detects signs of tampering, and flags inconsistencies early. This reduces fraud exposure and speeds up approval processes without expanding manual review teams.

Education

Educational institutions and edtech platforms use computer vision to validate scanned exams, certificates, and remote assessment inputs. Quality control here ensures legibility, completeness, and compliance with predefined formats, helping maintain fairness and accuracy across large student populations.

Insurance

Insurance relies heavily on visual evidence for underwriting and claims. Computer vision systems assess photo quality, detect manipulation, and identify inconsistencies between submitted images and reported events. This improves claim accuracy while reducing processing time and operational costs.

Automotive

In automotive manufacturing and servicing, computer vision inspects parts, assemblies, and finished vehicles at scale. Systems detect surface defects, alignment issues, and wear patterns that are difficult to catch manually, ensuring consistent quality across high-volume production lines.

Delivery

In delivery operations, quality control focuses on package condition and handling compliance. Computer vision monitors damage, verifies labeling, and confirms correct loading and unloading, helping logistics teams prevent disputes and improve customer satisfaction.

Across all these sectors, computer vision shifts quality control from subjective assessment to consistent, data-driven validation that scales with demand.

Architecture: Edge vs. cloud inference

Where computer vision runs matters as much as how it works. The choice between edge and cloud inference comes down to latency, cost, and operational risk, not preference.

Edge inference processes images directly on or near the production line. This minimizes latency, enables real-time decisions, and keeps sensitive data local. It fits environments where inspection must trigger immediate action, such as stopping a line or rejecting a part, but it requires upfront investment in hardware and ongoing device management.

Cloud inference centralizes processing, making it easier to scale, update models, and manage infrastructure. It lowers hardware complexity on-site and works well for non-time-critical inspections or large data analysis, but introduces latency and recurring compute costs.

In practice, most production systems use a hybrid approach: edge for real-time inspection and cloud for retraining, analytics, and long-term optimization. The right architecture is the one that meets timing requirements without inflating cost or operational complexity.

Implementation challenges and best practices

Most computer vision projects fail not because the idea is wrong, but because execution ignores production reality. Each common challenge has a practical way to handle it if addressed early. Here are some tips from us:

- Insufficient training data: Start collecting production images before model development begins. Focus on real defects, not just ideal samples, and plan for continuous data expansion as new edge cases appear.

- Inconsistent image quality: Lock down lighting, camera placement, and calibration from day one. Stable visual conditions matter more than model complexity.

- Changing production conditions: Treat retraining as a routine process. Materials, suppliers, and tolerances evolve, and models must evolve with them to stay accurate.

- Overfitting to test environments: Validate models directly on the production line, not just in controlled datasets. Real-world noise exposes issues early and prevents false confidence.

- Weak system integration: Define clear actions for every inspection outcome. A detected defect must trigger a response, whether stopping a line, flagging a batch, or logging an event.

The best way to minimize errors is to think of computer vision as a living system. Continuous monitoring, feedback loops, and incremental rollout keep accuracy high while reducing operational risk.

How Binariks helps implement computer vision for quality control

At Binariks, computer vision projects start with the production floor, not the model. The team works closely with engineering and operations to understand where defects emerge, how inspection fits into existing workflows, and what constraints matter most, from latency to compliance. This practical focus helps avoid over-engineered solutions and keeps systems aligned with real production needs.

Beyond model development, Binariks delivers complete, production-ready systems. This includes data pipelines, system integration, deployment strategy, and ongoing optimization as conditions evolve. Computer vision work is part of a broader AI/ML development services approach, designed to support long-term reliability rather than one-off experiments.

Conclusion

Computer vision changes quality control from a manual checkpoint into a measurable, scalable system. By removing variability and enabling continuous inspection, it helps organizations catch defects earlier, reduce operational risk, and maintain consistent standards as production grows.

The strategic value lies in control and predictability. Quality becomes something you can monitor, improve, and trust over time. If you are exploring how computer vision could fit into your quality processes, this is a good moment to contact Binariks and assess what a production-ready solution would look like in your environment.

Share