AI car damage detection is becoming a core tool for insurers and automotive companies to assess vehicle damage faster, cheaper, and more accurately. Instead of relying on manual inspections and subjective judgments, businesses now use computer vision and machine learning to detect damage directly from photos or video.

The result: instant diagnostics, streamlined claims, and lower operational costs.

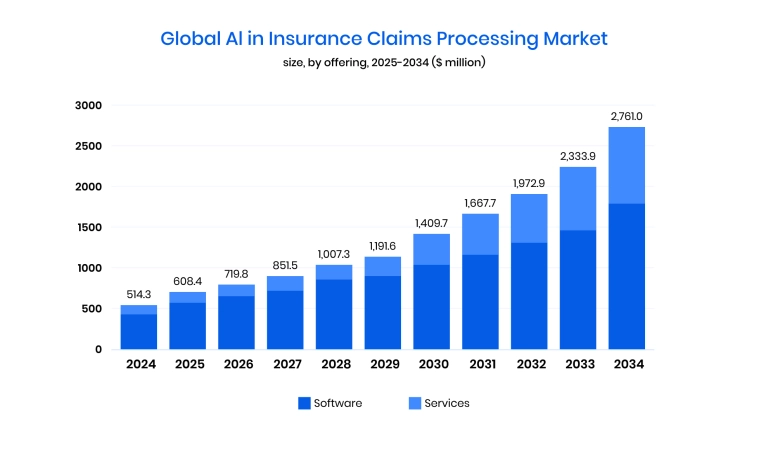

The impact is measurable. According to a 2025 market report, AI in insurance claims processing is projected to reach $2.76 billion by 2034, growing at a CAGR of 18.3%.

Another study published in Applied Sciences in 2024 analyzed real-world insurer use cases, demonstrating how automated car damage assessment systems can identify surface-level and structural damage with up to 90% accuracy. These systems accelerate claims, reduce fraud, and improve auditability — core challenges for insurers and fleet operators (Source ).

For insurers, AI enables faster claim resolution with minimal adjuster involvement. For auto repair shops, it delivers standardized damage reports and reduces diagnostic time. And for fleet managers, it allows consistent, scalable inspections across large volumes of vehicles.

Across the board, the technology helps the industry meet rising demand while cutting overhead.

This article covers:

- How AI-based damage detection systems work

- The machine learning models driving detection accuracy

- Applications in insurance workflows and claims

- AI's role in automotive repair and maintenance

- Current limitations and challenges

- Market examples of AI solutions in use

- A breakdown of the Binariks case study on AI-powered damage assessment system

Read on for a detailed look at how AI is changing vehicle damage detection and why adoption is accelerating across the insurance and automotive sectors.

How AI car damage detection works

Modern car damage detection systems rely on a combination of advanced imaging technologies and machine learning to interpret visual data from vehicles. The core principle is simple: analyze images or video of a car, detect visible damage, and classify its type and severity. Behind this simplicity is a complex tech stack that enables systems to deliver results in seconds, often with higher consistency than a human assessor.

Here's how these systems typically work:

- Computer vision

At the front end of the process, computer vision algorithms scan vehicle images to locate and highlight areas with potential damage. These models detect visual anomalies, such as dents, scratches, or cracks, by analyzing textures, contours, and surface patterns.

- Convolutional Neural Networks (CNNs)

A subtype of deep learning, CNNs are the backbone of most vehicle damage detection systems. They're trained on thousands of labeled images and can accurately classify damage types, even under varying lighting and angle conditions.

- Image segmentation

AI isolates the damaged regions from the rest of the vehicle image using segmentation techniques. This step ensures that further analysis focuses only on the relevant parts, improving precision and speeding up downstream processing.

- Damage classification and severity scoring

Once the damage is identified, it's categorized — scratch, dent, cracked bumper, broken light, etc. — and scored for severity. This scoring often follows insurer-specific rulesets, allowing for direct integration into claims systems.

- AI car image processing pipelines

These pipelines automate the intake, validation, and enhancement of incoming photos before analysis. They ensure images are of sufficient quality and standardize preprocessing tasks like resizing, brightness correction, and noise reduction.

- Integration with IoT and telematics

When paired with connected devices, AI systems can trigger IoT-based insurance workflows — for example, automatically requesting damage images after a collision alert from a telematics device.

In short, AI car image processing enables fast, scalable, and data-rich damage assessments. These systems are built to operate in real time, helping insurers, repair shops, and fleet operators make faster decisions with more confidence.

Models used in AI car damage detection

Effective car damage recognition depends on the right architecture for the task. Different models are used to locate, isolate, and classify vehicle damage, depending on the granularity and context of the inspection.

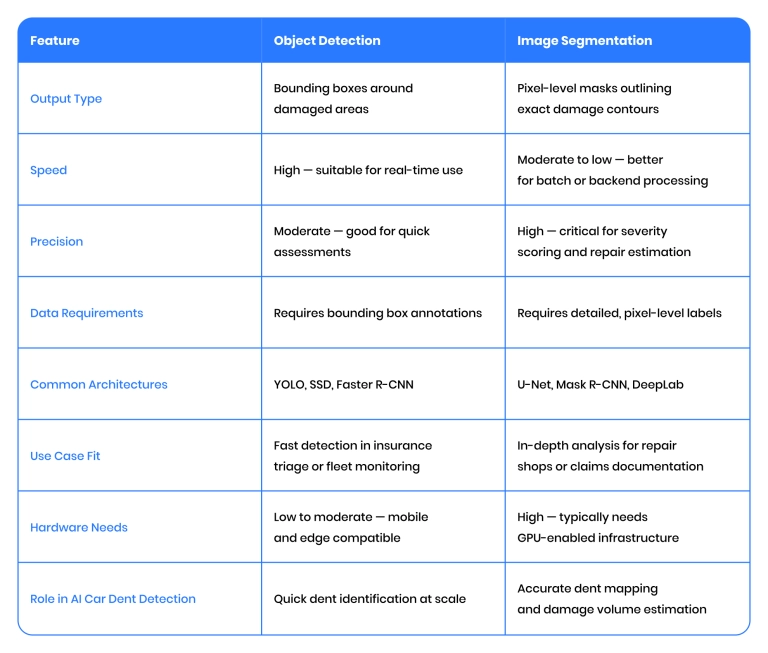

In production systems, object detection and image segmentation models are often combined to balance speed and precision.

Below are the two core model types powering AI car damage recognition systems.

Object detection models

Object detection models are designed to identify and localize damaged areas within an image. These models draw bounding boxes around vehicle parts that show signs of impact, such as dents, scratches, or cracks.

In AI car dent detection, object detection models help systems quickly flag areas of concern without analyzing the entire image in detail. They're particularly useful in real-time applications like mobile inspections or live video feeds. Popular architectures include:

- YOLO (You Only Look Once): Known for its speed, used in real-time detection on mobile and edge devices.

- Faster R-CNN: More accurate, better for complex or high-resolution inputs, but slower.

- SSD (Single Shot Detector): A middle-ground approach faster than R-CNN and more accurate than YOLO.

These models prioritize efficiency, making them ideal for high-throughput environments like insurance claim automation or large-scale fleet monitoring.

Segmentation models

While object detection shows where the damage is, segmentation models show exactly what's damaged. These models classify each pixel in an image, allowing systems to understand the shape and size of the damaged area with high granularity.

In advanced recognition pipelines, segmentation is used for detailed analysis and severity scoring. This is especially important in scenarios where repair cost estimates are needed. Key segmentation model types include:

- U-Net: Effective in pixel-level precision tasks and widely used in medical imaging, adapted here for vehicle damage.

- Mask R-CNN: Extends Faster R-CNN with a segmentation branch, making it ideal for combining object detection and segmentation in one pipeline.

- DeepLab: Designed for complex segmentation under challenging visual conditions, such as poor lighting or occlusion.

Segmentation models are more computationally intensive but offer superior precision for downstream tasks like damage scoring or automated repair suggestions.

Comparison: Object detection vs. segmentation

In most production environments, AI car damage recognition solutions use both models in tandem. Object detection enables quick assessments and triaging, while segmentation provides the detail required for precise repair estimates and audit-grade documentation. Together, they form the core of intelligent, scalable damage assessment pipelines.

AI car damage detection in the insurance industry

Insurance companies are pressured to process more claims faster while keeping costs and fraud in check. One major advantage of using technology to detect damage with AI is the automation of vehicle assessments, which traditionally relied on manual inspections.

By analyzing photos or videos submitted by customers, AI models can identify damage, classify severity, and recommend next steps — all in minutes. This cuts down processing time from days to hours, reduces reliance on adjusters, and enables straight-through claims handling.

In parallel, AI is helping insurers address long-standing challenges like fraud and inconsistent reporting. With an advanced AI damage detection model, insurers gain more standardized, objective data, which is also easier to audit. And when these models are combined with pattern recognition systems, they help insurers detect insurance fraud using AI — catching duplicated claims, photo manipulation, and staged accidents more effectively than traditional rule-based systems.

Real-world cases

- British insurer Ageas implemented a photo-based assessment tool that lets policyholders upload images of their vehicle after an incident. The system applies AI-driven car damage detection to estimate the damage instantly, enabling the insurer to offer repair or payout decisions within minutes. This drastically cut the call center load and improved the overall claims experience (Source ).

- Deloitte developed a modular solution to support end-to-end claim automation. Their system uses layered computer vision and deep learning to detect damage, assess severity, and link results to compensation recommendations. Insurers can adjust human involvement based on confidence thresholds, improving operational control and trust in automated assessments. This flexible approach is gaining traction in large-scale enterprise rollouts of AI car damage recognition (Source ).

- KBTG Labs collaborated with Muang Thai Insurance PCL (MTI), a leading insurance provider in Thailand, to enhance their vehicle damage claims validation and settlement process using AI. Traditionally, assessing vehicle damage involved manual evaluations by repair shops, followed by validation from insurance intermediaries — a time-consuming and costly process. To address these challenges, KBTG developed the Image Qualifier model utilizing Google's Vertex AI. This model classifies input images to ensure they meet quality standards before further analysis, streamlining the claims process. By incorporating Explainable AI, the system provides transparency in its assessments, allowing for better understanding and trust in the AI's decisions. This implementation has led to more efficient and accurate claims processing, benefiting both the insurer and policyholders (Source ).

These cases illustrate the diverse applications of AI in the insurance and automotive industries, highlighting improvements in efficiency, accuracy, and customer satisfaction.

Embrace InsurTech innovation with custom software development

AI in automotive repair and maintenance

Auto repair centers are also increasingly turning to artificial intelligence to improve speed, accuracy, and cost-efficiency in diagnostics.

Often time-consuming and inconsistent, manual inspections are being replaced with automated damage detection systems that rely on computer vision and machine learning. These systems allow service centers to scan a vehicle in seconds, identify exterior and structural issues, and generate repair estimates with minimal human intervention.

The benefit goes beyond speed. With AI car damage inspection, shops gain a standardized method for identifying damage — whether it's a scratch on the fender or a misalignment in the undercarriage. This leads to faster service, more accurate parts ordering, and better communication with insurance providers. As AI becomes more accessible and scalable, it's setting a new standard for automotive dent detection and repair workflows.

Real-world cases

- UVeye developed a computer vision-based system capable of scanning vehicles in seconds to identify and report issues. Initially designed for military applications, the technology has been adopted by car rental companies, fleet operators, and dealerships, including Amazon. The system processes approximately 500,000 vehicles monthly, providing rapid and accurate condition reports that streamline maintenance and resale processes (Source ).

- DeGould's AI solutions are used at OEM factories and logistics centers to conduct ultra-precise image-based damage inspections. The system automates vehicle handover quality checks and uses AI to detect and document issues down to minor blemishes, delivering consistency that manual inspection simply can't match. It also supports claim documentation and pre-delivery audits (Source ).

- ProovStation offers a drive-through scanning station equipped with AI to detect damage and alterations across 250+ high-resolution images captured per vehicle. Used by repair facilities, leasing companies, and fleet operators, the system delivers an automated condition report that improves inspection transparency and repair planning. This streamlines operations and reduces reliance on human visual inspections (Source ).

These examples show how automated inspection is changing the way repair centers operate — reducing manual guesswork, improving diagnostic consistency, and speeding up service. As the industry moves toward more connected and data-driven operations, this technology quickly becomes a practical edge for businesses, not just a technical add-on.

Challenges and limitations of AI in car damage detection

While AI offers clear advantages in speed and consistency, deploying it at scale in AI vehicle damage inspection still comes with significant challenges. Several factors affect how reliably these systems perform under production conditions, from data quality to real-world variability. Let's consider some of them.

Inconsistent image quality and user variability

AI models are only as good as the images they receive. Poor lighting, obstructions, reflections, or low-resolution cameras reduce detection accuracy. In user-submitted workflows, problems multiply — untrained users may submit blurry or poorly angled photos, leading to missed or misclassified damage. This remains a key barrier to dent detection in the automotive industry, especially for consumer-facing apps.

Limited generalization across vehicle types

Models trained on specific vehicle types or localized datasets struggle to generalize to a broader range of makes, models, or regional damage patterns. For example, a system tuned for compact sedans in North America may underperform when inspecting pickup trucks in Latin America. This lack of generalization makes AI vehicle damage detection less reliable when scaled globally.

Environmental and contextual noise

Backgrounds, shadows, weather effects, and visual obstructions (like dirt or aftermarket parts) interfere with detection accuracy. According to Inspektlabs, overexposed or underexposed photos and reflective surfaces are common causes of AI errors. Without standardization in image capture conditions, models are exposed to too much noise to consistently produce reliable results (Source ).

Difficulty handling edge cases and subtle damage

AI systems often perform well on clear, visible damage but struggle with borderline or complex cases like scratches on black vehicles, hairline cracks, or damage under glare. These are harder to detect consistently, and false negatives are common. Human inspection is still needed in high-complexity scenarios or where legal liability is involved.

Regulatory, legal, and trust barriers

The lack of explainability in some AI systems raises concerns in insurance contexts, where every decision needs to be transparent and auditable. If an AI vehicle damage inspection system makes a flawed assessment, the insurer could be liable. To balance automation with accountability, many insurers are now adopting hybrid approaches powered by adaptive AI — blending machine learning with real-time feedback and human input.

Cost and complexity of data labeling

Training accurate models requires massive labeled datasets, often annotated by auto repair professionals or insurance adjusters. Variations in annotation quality and inconsistent severity scoring introduce additional errors. Building and maintaining such datasets is costly and time-consuming, especially for cases requiring fine-grained severity grading.

AI has unlocked new levels of automation in AI vehicle damage detection, but its performance still hinges on structured environments, well-curated data, and thoughtful deployment. To move from pilot to production, companies must tackle challenges ranging from image variability to legal compliance while investing in adaptable systems that evolve alongside real-world conditions.

Examples of AI car damage detection solutions

Major players in tech and consulting are actively developing advanced AI vehicle damage detection tools to support insurers, automakers, and repair networks. These solutions help accelerate claims, reduce fraud, and deliver consistent repair estimates using machine learning and computer vision. Below are three of the most prominent and widely adopted enterprise-grade platforms.

Ravin AI – comprehensive vehicle inspection system

Ravin AI offers a powerful inspection application that uses AI to capture photos, assess damage, and deliver accurate, actionable insights. This technology enables insurers to make faster claim decisions and provides fleet operators with efficient vehicle condition assessments. Ravin AI's solutions are designed to be user-friendly and can be deployed using standard smartphone devices, making them accessible and scalable for various applications (Source ).

IBM Watson – visual recognition for insurance

IBM Watson provides AI-powered visual recognition services that have been applied to vehicle damage analysis. By leveraging Watson's capabilities, insurance companies can automate vehicle damage assessment from images, significantly reducing the time required for claims processing. For instance, Turkey's Anadolu Insurance implemented IBM Watson's Visual Recognition Service, cutting the time for uploading and examining vehicle photos during damage assessments by 70% (Source ).

Tractable – end-to-end AI claims automation

Tractable is one of the most widely adopted platforms for car damage detection using deep learning. It enables insurers and repair networks to process claims based on customer-uploaded photos, generating instant repair assessments. Companies like GEICO and Beesafe use Tractable to resolve claims in minutes, scaling operations while maintaining accuracy (Source ), (Source ).

Binariks' approach to a car damage assessment

Binariks' approach to a car damage assessmentAn EU-based insurance company addressed Binariks with a clear problem: their damage assessment solution was outdated. Claims required slow, manual evaluations by brokers, leading to delays, higher operational costs, and growing customer frustration. Every image had to be reviewed by hand, creating bottlenecks in the claims process and putting pressure on internal teams.

To address this, Binariks engineered an AI-powered application built specifically for insurance-grade AI vehicle damage detection.

We started with transfer learning, applying pre-trained models to a new dataset of annotated car damage images. At the core of the system is a Region Proposal Network (RPN), which automatically identifies where damage is likely to appear in an uploaded image. From there, a secondary classification model analyzes the image and distinguishes between six types of damage: dent, scratch, crack, glass shatter, broken lamp, and tire flat.

What sets this apart is the model's ability to associate each damage with specific car parts using segmentation mask overlap. Once a photo is uploaded, the system first identifies the vehicle's structure and then isolates damage within each region. It also aggregates metadata such as car model, manufacturing year, and severity level, enabling more precise and context-aware assessments.

With this solution, our client replaced their manual process with accident damage estimation through ML, reducing claim processing time, lowering administrative overhead, and significantly improving the customer experience.

AI-powered app for car damage assessment

We developed an app that automates damage assessment, accelerates claim approvals, and reduces costs.

Conclusion

AI is changing how insurers, auto service providers, and fleets handle vehicle damage — from faster claims processing to more consistent repair assessments. With technologies like computer vision, deep learning, and segmentation models, AI damage detection is no longer experimental — it's already delivering measurable impact. Companies that embrace accident damage estimation through ML are reducing operational costs, improving fraud detection, and streamlining the customer experience at scale.

At Binariks, we help businesses unlock this potential with custom-built, production-ready AI solutions. Whether you're looking to build a damage assessment solution from the ground up or enhance an existing workflow, we bring deep expertise in machine learning, image recognition, and cloud integration. If you're ready to move beyond manual inspections and build scalable, intelligent systems — contact us today.

Share